An automotive thermostat serves as a sentinel for your engine, vigilantly controlling the flow of coolant to maintain optimal operating temperatures. This comprehensive guide offers an in-depth exploration of the intricacies involved in the functioning of an automobile’s thermostat.

Delve into its key components, understand its critical role in engine efficiency, learn to recognize symptoms of malfunction, and get insights into replacing it when required.

Demystifying the Function of an Automotive Thermostat

While often underestimated in its importance, the thermostat in an automobile is essential for regulating the engine’s optimal temperature levels. It serves as a gatekeeper for the cooling system, ensuring that the engine neither runs too cold at startup nor overheats during sustained driving.

As an integral part of the engine’s cooling mechanism, it adjusts coolant flow in response to engine temperature, thereby enhancing both performance and efficiency.

Unpacking the Fundamental Operations of a Thermostat

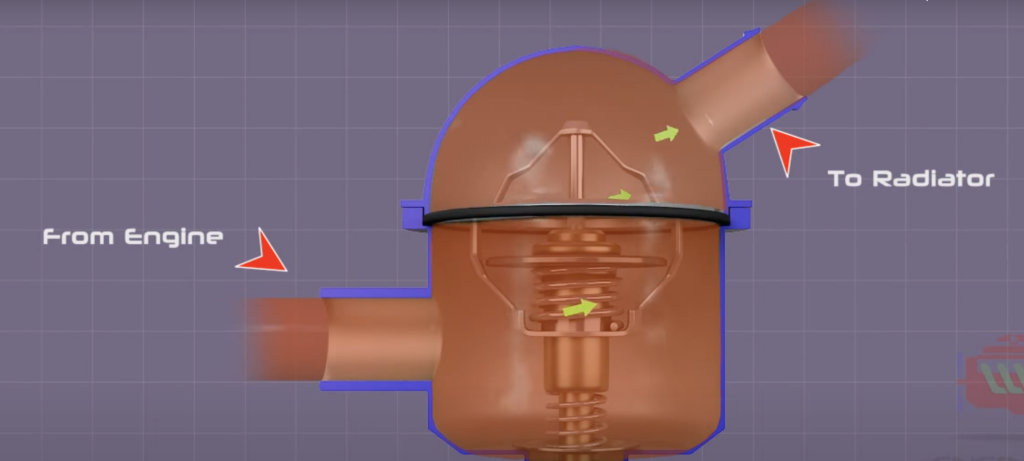

The quintessential role of an automotive thermostat is to manage the circulation of coolant between the engine and the radiator. In the engine’s initial operational phase, the thermostat stays in a closed position, preventing the cooling liquid from entering the radiator and facilitating the engine’s ability to reach its optimal temperature swiftly. Here’s how the thermostat accomplishes this:

- Temperature Monitoring: Throughout the initial phase, the thermostat vigilantly assesses the temperature of the engine. Its goal is to facilitate the engine in reaching its optimal functioning temperature with maximum efficiency;

- Coolant Circulation: By keeping itself closed initially, the thermostat directs the coolant to circulate only within the engine block, thereby absorbing the heat generated from combustion processes;

- Transition Phase: Upon the engine hitting the desired temperature range, the thermostat enters its open state, enabling the coolant to circulate through the radiator. Here, the coolant dissipates its absorbed heat before returning to the engine.

The Thermostat’s Critical Role in Engine Efficiency

Maintaining the engine at a precise temperature is paramount for optimal engine performance. Overheated engines can lead to catastrophic damage, including compromised cylinder heads and gaskets. Simultaneously, an excessively cold engine can degrade fuel efficiency and increase emissions due to incomplete fuel combustion. Therefore, the thermostat serves as:

- A Protective Guardian: By carefully managing coolant flow, it ensures that the engine functions within the parameters set by the manufacturer, thereby safeguarding performance and fuel efficiency;

- Climate Adaptive: Especially in colder climates, the thermostat aids in swiftly warming up the engine, thus facilitating the rapid achievement of optimal operational conditions. This functionality not only enhances engine efficiency but also ensures that the cabin heating system becomes effective more quickly.

Elements Constituting an Automotive Thermostat

A thermostat within the automotive sphere is not a standalone piece but a complex assembly of various components such as the wax pellet, valve, spring, and housing.

The Role of the Wax Pellet

The wax pellet is an intricate part of the automotive thermostat assembly, crafted from a combination of specialized wax and a heat-responsive material.

- Heat Sensitivity: The wax pellet houses a chamber filled with specialized wax with a specific melting point. When the engine attains a certain temperature, the heat-sensitive material activates the melting process;

- Responsive Mechanism: The pellet’s highly sensitive nature ensures prompt and accurate adjustments to coolant flow, thereby averting both overheating and unnecessary cooling of the engine.

An automotive thermostat may be compact in size, but its role is monumental in ensuring that an engine operates at peak efficiency and longevity. By meticulously regulating coolant flow, it serves as the first line of defense against both overheating and suboptimal performance conditions.

Understanding its functionality and key components can equip you with the knowledge to maintain your automobile in optimal working condition. So, the next time you ignite the engine, take a moment to appreciate the intricate engineering of the thermostat, ceaselessly working to maintain your engine’s health.

The Valve Component in Automotive Temperature Regulation

The valve, a critical part of an automobile’s thermal management system, functions as the regulating point through which the coolant passes. Directly influenced by the wax pellet’s actions, this valve’s status—whether open or shut—varies according to the expansion of the pellet. During initial engine activation when the motor is still at a lower temperature, the valve remains in a closed state to impede the movement of coolant.

Constructed usually from hardwearing materials like stainless steel, the valve is designed to resist extreme thermal conditions and elevated pressures. Its architecture ensures an impermeable closure, thereby precluding any potential leaks. When subject to the force generated by the expanding wax pellet, the valve alters its state from closed to open.

Within the valve are meticulously designed pathways and channels. These routes:

- Facilitate uniform coolant distribution within the engine;

- Optimize thermal exchange;

- Regulate temperature efficiently.

The Role of the Spring in Thermal Management

In concert with the wax pellet and valve, a spring performs a vital role in modulating the coolant’s circulation. The spring counterbalances the force exerted by the wax pellet, contributing to controlled and methodical valve movement. Such counteraction stabilizes the coolant flow and deters abrupt temperature swings in the engine.

The spring is fashioned from robust, enduring materials like steel to endure repetitive pressures and mechanical movements. It is finely tuned to apply just the right counterforce against the wax pellet, thus enabling the thermal control mechanism to function in a refined manner.

As the motor cools and the wax pellet retracts, diminishing its outward force, the spring acts to reseal the valve. Consequently, the movement of the coolant is once more confined until the motor’s temperature escalates anew.

Thermostatic Housing: The Protective Shell

Beyond the wax pellet, valve, and spring, there’s a housing unit that serves as the protective case for these temperature-regulating components. This encasement is generally crafted from robust materials like aluminum or engineered plastics capable of withstanding the engine compartment’s rigorous conditions.

Within this housing are:

- Channels and routes that guide coolant flow;

- Designed to minimize turbulent flow and pressure inconsistencies;

- Engineered to allow for undisturbed circulation of coolant.

Moreover, the housing incorporates points for mounting and connecting, ensuring the thermal management system’s correct alignment with the engine, thereby augmenting its operational efficiency.

The Operative Dynamics of Automotive Thermal Control Systems

The thermal control unit operates via a straightforward yet competent method, achieving ideal thermal conditions within the motor.

The Process of Heat Buildup

At the moment the engine springs to life, the valve restricts coolant from moving. The rapid heat buildup prompts the wax pellet to swell and eventually nudges the valve to an open state, permitting coolant to pass through the cooling unit and subsequently re-enter the engine, now at a reduced temperature.

The Cooling Sequence

Reaching the perfect operational temperature signals the wax pellet to halt its expansion, allowing the spring to exert adequate counterforce to partially or fully close the valve. This limited coolant flow reduces the cooling action and helps the motor to sustain its most effective working temperature.

Recognizing Signs of a Degraded Thermal Regulator

Automotive temperature regulators aren’t immune to wear and tear and can manifest malfunctions over their lifespan. Timely identification of these symptoms is crucial to averting further complications.

Motor Overheating

When the engine becomes excessively hot, it’s often indicative of a malfunctioning temperature control mechanism. If the valve is unable to transition to an open state due to failure, it hampers the flow of coolant.

Consequently, the engine temperature can reach dangerous levels, putting various motor components at risk of damage. Immediate intervention is necessary to prevent severe and costly outcomes.

Unstable Dashboard Temperature Gauge: What It Indicates

When the temperature gauge on the dashboard exhibits erratic behavior, this typically serves as a red flag for a potential issue in the engine’s temperature control system. Such unpredictable readings commonly point to an uneven flow of coolant, a situation most often linked to a malfunctioning temperature management mechanism.

Additional Signs of an Issue:

- Sudden spikes or drops in displayed temperature;

- Gauge needle getting stuck at high or low temperatures;

- Unusual engine noise accompanying the fluctuating gauge readings.

The Protocol for Swapping Out a Faulty Engine Temperature Regulator

In the event that the engine temperature control mechanism is determined to be defective, substituting it with a new one is generally advisable. This procedure is a delicate operation, requiring not only the right timing but also the precise execution of each step. Such meticulous attention to detail is essential for guaranteeing an uneventful and successful replacement process.

Key Considerations:

- Consult the service manual for model-specific instructions;

- Consider seeking professional assistance for more complex models;

- Budget for the cost of a high-quality replacement part, as well as any tools needed.

Optimal Timing for Changing an Engine Temperature Regulator

Recognition of any outlined symptoms or other signs of a failing engine temperature control unit should prompt its immediate replacement. Moreover, preemptively swapping out this component during routine engine check-ups is generally viewed as a prudent practice. Doing so can forestall unforeseen malfunctions and potential resultant damage to the engine.

Additional Reasons for Preemptive Replacement:

- Age of the automobile: Older models may require more frequent replacements;

- Mileage: Some manufacturers recommend replacement after a specific number of miles;

- Previous issues: If the engine has had cooling issues before, a proactive replacement may be wise.

Methodical Procedure for Substituting an Engine Temperature Regulator

Exchanging a defective engine temperature regulator is a multi-step endeavor. Initially, one must confirm that the engine has adequately cooled down to sidestep the risk of thermal injuries. Thereafter, the cover of the temperature regulator’s enclosure must be located and detached, along with any other components obstructing access.

Subsequent to excising the old unit, the adjoining surfaces should be diligently cleaned before installing the replacement part in the correct alignment. The final steps involve reattaching all previously disassembled parts, refilling the coolant reservoir, and carrying out a leak assessment.

Checklist for the Replacement Process:

- Safety gear: Gloves and eye protection are highly recommended;

- Tools: Usually, a wrench, screwdriver, and potentially a gasket scraper will be needed;

- Coolant: Ensure a supply of compatible coolant for replenishing the system;

- Leak check: After installation, run the engine briefly to ascertain there are no leaks.

Conclusion

Comprehending the intricacies of the engine’s temperature management system, its constituent elements, and the tell-tale signs of malfunction allows for effective preventative maintenance.

Scheduled inspections and prompt substitutions of faulty components are instrumental in maintaining the engine’s temperature within the ideal bounds. Adhering to these best practices ensures not only the longevity of your automotive asset but also its efficient operation.